Posted on May 25, 2023 at 6:42 PM

Strategies for Mitigating Risk in the Manufacturing Attack Surface

Thanks to the innovation of digitalization initiatives, Operational Technology (OT) and Information Technology (IT) are no longer isolated as they used to be. This led to a digital transformation of the factory floor, which has sped up the connection of machines to digital systems and data.

Now, computer systems are capable of managing everything and monitoring the entire production process, and they were added to the hardware and software that is used for monitoring all industrial devices and machines. Everything is connected, including OT and IT.

Of course, this means that productivity has been enhanced further than ever before. On top of that, the lack of workers has reduced operational costs, while the process of producing virtually anything is faster than ever. The only area where this entire system now suffers is security, and because everything it susceptible to hacking attacks, the entire organization is at risk.

Last year alone, manufacturing systems around the world suffered a total of 2,337 attacks.

Ransomware is putting manufacturers at risk

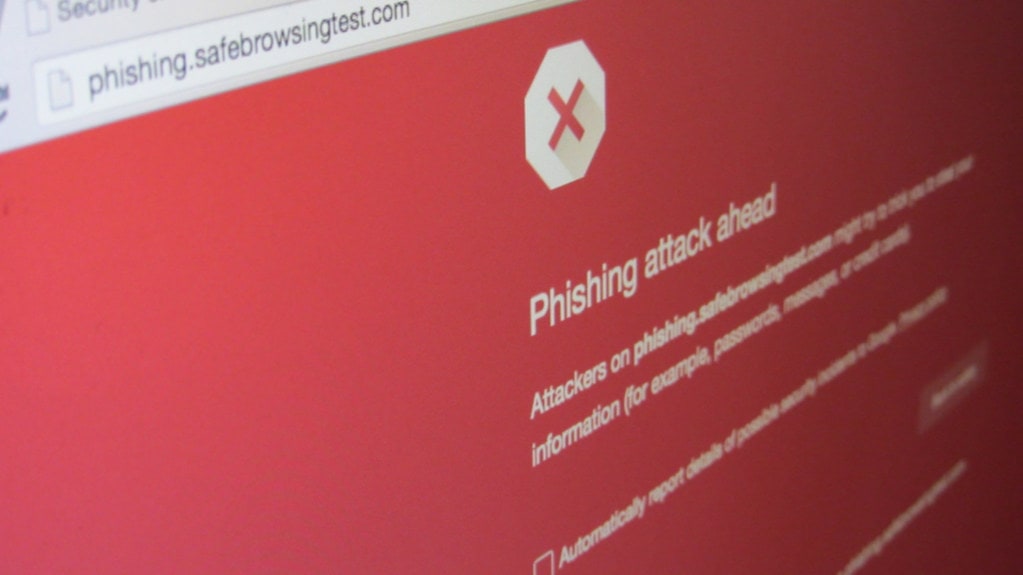

Speaking of hacking attacks, they are also different than they used to be. Their nature has changed, and while in the past, attackers have been espionage-driven, targeting secrets and intellectual property, today they are stealing credentials and locking machines with ransomware, forcing companies to pay up or fail.

In fact, manufacturing has been the primary target of ransomware attacks in 2022, with an 87% increase compared to the previous year. The worst part is that most manufacturers are still not ready to deal with an attack of this kind, despite being aware of the danger. Security Scorecard estimated that nearly half of the reviewed manufacturing companies had scored a C, D, or F in security. As such, they are practically defenseless when attackers come knocking.

The average cost of a critical infrastructure data breach sits at $4.8 million. Meanwhile, high-profile incidents have recently shown how crippling these attacks can be. For the most recent example, remember the attack on Dole Company, one of the world’s largest producers of fruit and vegetables. After being targeted by online criminals, the company had to shut down its production in North America.

In August 2022, two companies from Luxembourg were hit with ransomware, and the attackers managed to take down customer portals and steal data from the systems. Not to mention the Colonial Pipeline attack, which really put the faulty infrastructure under the spotlight.

How can Manufacturers Reduce Exposure to the Attack Surface?

So far, we have talked about the problems that manufacturers face due to weak security, but what can they do to protect themselves better? Well, plenty of different steps can be taken, and right now, we can present five of them that should give you an edge in keeping the hackers out.

1. Multiple tests

Manufacturers should not underestimate the positive impacts of regularly testing and assessing their networks and infrastructure. This will provide them with real-time visibility into their security status. By testing again and again, they can identify flaws as soon as they appear or pick up on something that they missed previously.

Not only that, but they will even be able to evaluate the efficiency of their security controls, identify areas that require additional work, adjust their security program, raise awareness, and more. So, not only will they be safer, but they will also get a competitive edge simply by being more secure than competitors.

2. Automating security process

Automation has worked wonders for production, and it can do the same for security. Through automation, companies can find optimal use of time and resources. This efficiency will help streamline their efforts, reduce the time and effort needed to identify security threats and respond to them, and more. Organizations can start by automating the testing of the network and make it run again and again at regular intervals.

Through automation, firms can reach standardization, accuracy, and through them — consistency. As a consequence, they will even be able to scale and boost their security practices, all with great cost-efficiency. With everything becoming available at a click of a button, there is no reason for firms to avoid this step.

3. Think like a hacker

In order to understand what an attacker may target, you need to learn to think like one. Regardless of why a hacker might target your systems, they will first look for a way in. This is why organizations must think outside of the box and try to find potential vulnerabilities before bad actors do.

By taking this adversarial perspective, they can improve their security strategies and minimize the chance of being hacked.

4. Prioritize patching based on actual risk

Another cost-effective way of mitigating risk and reducing exposure is by prioritizing vulnerability remediation based on business impact. Simply put — that which matters most must come first. Companies should start by patching the most critical vulnerabilities and threats that testing reveals, then work towards the least critical ones.

Flaws that could expose your business to the greatest amount of damage should be the first to be patched, otherwise, you might be wasting your time with an unimportant error while giving the hackers an opportunity to find their way in.

Furthermore, prioritization is also a great way to eliminate the “noise” caused by too many security alerts. By removing the big one, you might also eliminate some small ones that only exist because of the big ones.

5. Benchmark your security posture

Lastly, we should remark that regular testing of your attack surface can continuously benchmark your security posture. This is helpful in a number of ways. For example, it allows you to measure the effectiveness of your security measures compared to the best industry practices. It can also reveal areas where improvement is possible or even necessary.

It can demonstrate compliance with industry standards and regulations, and it will also grant you valuable insight into your security strategy and posture. That way, you can make better, more informed decisions moving forward.